About Us

The famous ‘Pitch Lake’ in the small community of La Brea in Trinidad and Tobago is not only a site which draws hundreds of Tourist to the Southern portions of the Island of Trinidad annually, but is the single largest commercially mined deposit of natural asphalt in the world.

While wading in the small pools of water which collect on the surface of the Pitch Lake and musing on the ‘magical healing” powers which the water is said to have, based on its heavy sulphur content – a visitor to the lake may not connect the large, black expanse of pitch – in this remote part of a relatively tiny Caribbean island, with some of the world’s most heavily trafficked highways, international airport runways and bridges in Europe and the United States of America.

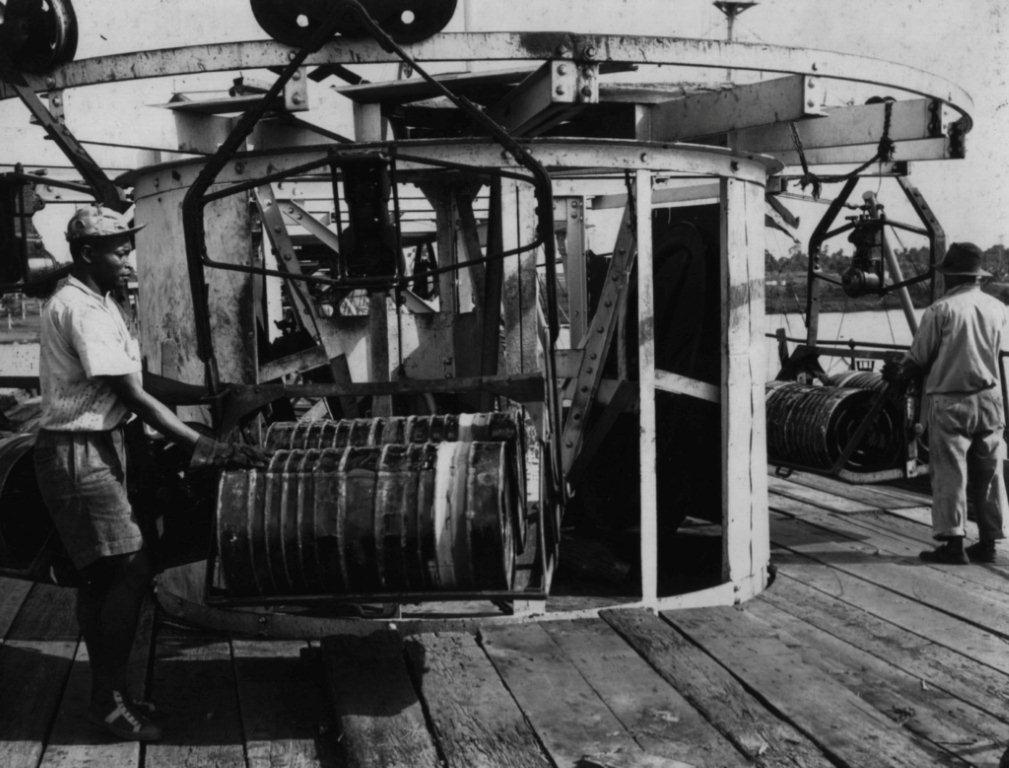

If the visitors would lift their gaze from the lake’s surface, they will see the commercial and production facilities of a Company whose history dates back to the 1800’s. This Company, Lake Asphalt of Trinidad and Tobago (1978) Limited, with just over 200 employees, is one of largest earners of foreign exchange in the twin island state of Trinidad and Tobago.

The company is fraught with paradoxes. Its headquarters are located in a quiet, peaceful community but its road paving products are applied to major infrastructure projects in some of the most crowded, bustling cities in the world. It is a company steeped in history and tradition, but is the center for some of the most cutting edge asphalt research projects. 90% of its workforce lives in and around the community, while 90% of the revenue from sales of its core product, Trinidad Lake Asphalt (TLA) comes from export.

Trinidad Lake Asphalt (TLA) is the scientific name used to describe asphalt after it has been refined, through an amazingly simple process of heating and sifting out of stones, and other extraneous matter. TLA has become the benchmark of competing road paving materials throughout the world. Trinidad Lake Asphalt exhibits a wider performance range over conventional asphalt cements and offers exceptional resistance to deformation, low thermal sensitivity and great strength under extreme climatic conditions.

In addition to TLA, the company manufacturers a range of bitumen emulsions through a State of the Art Bitumen Emulsion Plant, a line of asphalt based coating – the TLA range of products and refinery bitumen which it purchases from one of the country’s leading petroleum companies.

Translate

Translate